The application of leak detection equipment in the field of automobile air tightness detection: the key purpose is to detect the air tightness of automobile products, waterproof detection, air tightness detection, such as automobile control board air tightness detection, battery bag air tightness leakage detection, etc

Automobile parts enterprises have the application of automobile air tight leak detector (namely, waterproof detection and airtight detection) in the following areas:

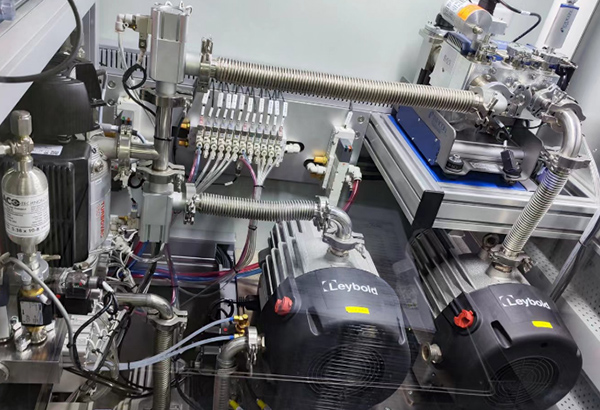

Automobile air tightness leakage test applied to RF connector air tightness test: It is stipulated that the tightness of RF connector will be tested under vacuum condition or positive pressure, and the air tightness test will be carried out after the equipment is sealed by fixture.

Automotive gas tight leak detector is applied to waterproof detection of surveillance cameras: IP66 waterproof detection level or IP67 waterproof detection level is generally selected, and the detection working pressure is 20 to 40KPA positive pressure or negative pressure detection method. The leakage rate is not more than 50PA.

Automobile air-tight leak detector in the new energy technology automobile battery bag air-tight leakage detection: choose immediate pumping method (direct pressure method) detection, the volume is relatively large, in order to improve the efficiency of air tightness detection, can choose the prior pumping method. Leakage rate generally does not exceed 150PA for standard.

Automobile gas tight leak detector is used for the air tightness detection of control panel and wheel air tightness detection. It is generally stipulated that the positive pressure or negative pressure detection is between 15kpa and 100kpa. The gas tightness detection is carried out after the commodity is sealed by fixture. The leakage rate of detected commodities is generally not more than 1cc/min for qualified products, that is, IP67 waterproof detection.